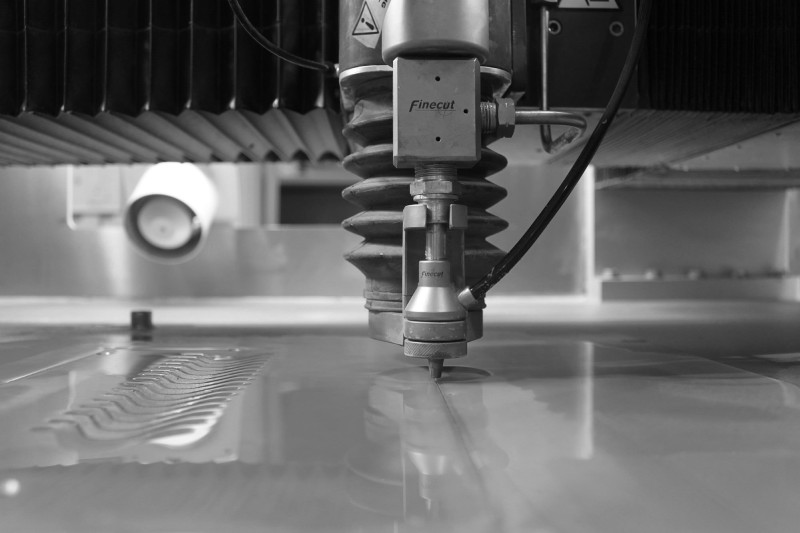

Experience the extraordinary world of Finepart, where manufacturers of advanced products made from high-value materials unlock the pinnacle of precision cutting. Through their cutting-edge non-thermal micro abrasive waterjet technology, Finepart is revolutionizing the industry, providing impeccable results with unmatched quality.

Finepart Sweden AB, a renowned and innovative company, is dedicated to developing and selling the groundbreaking FinecutTM machine. This remarkable piece of engineering allows for manufacturing components with exceptional precision. Since its inception in 2006, Finepart has been on a continuous growth journey, constantly striving to surpass milestones and reach new heights. Finepart’s innovation lies at the core of its micro abrasive waterjet cutting technology. By utilizing ultra-high-pressure water, this process generates a powerful jet that propels fine grit particles, effectively eroding material through particle erosion. The result is a cutting technique that offers outstanding accuracy while avoiding thermal damage to the workpiece. Throughout its history, Finepart has unveiled a series of advancements that have shaped its success. In 2008, they proudly presented the first functional prototype of the Finecut machine, featuring their proprietary micro-cutting systems, FAW200 and FAW300. The refined Finecut machine made its public debut at the Tekniska mässan in Stockholm, Sweden in 2009, captivating audiences with its precision and performance. In 2012, Finepart Sweden AB was established, acquiring all the rights, patents, and trademarks from Finecut AB, including the talented individuals behind the Finecut technology. Dr. Christian Öjmertz and research engineer Mr. Don Miller, the principal engineers, have remained integral to Finepart’s continued success, leveraging their expertise and knowledge to push the boundaries of precision cutting. Over the years, Finepart has introduced various enhancements and additions to its product lineup. In 2013, they launched the Finecut 4X, a cutting-edge machine featuring a rotary table. The following year, they achieved another milestone by selling and installing their first 5-axis Finecut machine at a customer location. As they continued to innovate, they introduced the Touch probe option in 2014, further expanding the capabilities of their devices. To solidify its position in the industry, Finepart Sweden AB became a public company and was listed on the Spotlight stock market in 2016, marking a significant milestone in its corporate journey. Their commitment to pushing boundaries persisted. In 2019, they unveiled the Finecut B4X, a remarkable 5-axis configuration that combines a tilting cutting head with a rotary table, enabling the cutting of intricate 3D geometries. The following year, they refined their 5-axis configuration and launched the Finecut ABX, showcasing their relentless pursuit of perfection. In 2022, Finepart introduced the “Finecam,” a unique high-resolution video measurement system, providing customers with advanced measurement capabilities to further enhance their cutting processes. Finepart owes its success to several key factors; Their highly skilled and innovative team, with decades of experience in waterjet technology, is crucial in providing cutting-edge manufacturing solutions. Furthermore, their proprietary cutting system design, featuring jet diameters as small as 200 microns, combined with precise motion control and advanced engineering, sets them apart from competitors, delivering parts with unparalleled geometric accuracy. The ingenuity of their machine design, incorporating state-of-the-art technology and components, offers flexible and sophisticated solutions to complex manufacturing challenges. At the heart of Finepart’s operations lies a customer-centric approach. They strive to understand their client’s unique requirements and challenges, working closely with them to achieve technical success. By offering initial production of customer parts, optimizing processes, and even providing the option for customers to produce their parts at Finepart’s facilities, they ensure a seamless and swift implementation of their technology. In the mesmerizing tale of Finepart, we witness the convergence of vision, innovation, and sheer determination. It is a saga that propels us into a world where precision knows no bounds, where the dance of water and grit shapes the future of manufacturing. With Finepart, manufacturers embark on a transformative journey guided by the marvels of micro abrasive waterjet technology. It is a realm where traditional cutting methods pale compared to the finesse and accuracy achieved through the gentle force of high-pressure water and meticulously propelled abrasives. Topics #Finepart #Non-Thermal Cutting Technology #Non-Thermal Micro Abrasive Waterjet TechnologyFinepart: Revolutionizing Precision Cutting with Non-Thermal Micro Abrasive Waterjet Technology

Random Posts

Is Lord Conrad dating the stunning top Model Olga Mikhaljova?

Their close relationship was upped a level up after they got close while working modeling together. Lord told to music…

4 New Affordable Electric SUVs Will Soon Be Coming

Future years will see a number of EV releases, raising the prospect of EVs and hybrids coexisting. Early 2025: Hyundai…

Openmonet, a Crypto P2P exchange startup with innovative solutions to disrupt the fiat-to-crypto exchanges

Openmonet is a Crypto exchange and electronic trading startup that brings innovative solutions to speed up the fiat-to-crypto exchanges among…

Victor Madu reveals his ambitious expansion plans for “For the Leaux” in 2021 and beyond

Even when a brand is flourishing, it’s important to always be hustling and working towards new heights. Victor Madu is…

Honour X9c Released with IP65M Rating and Snapdragon 6 Gen 1: Features and Cost

On Tuesday, the Honour X9c was introduced in Malaysia. A Snapdragon 6 Gen 1 SoC and up to 12GB of…

You guys got the praise when Umran performed. But this year… : Brian Lara and company exposé from a former SRH star

The former Sunrisers Hyderabad star criticised the team’s management over Umran Malik’s treatment during IPL 2023. Despite being eliminated from…